CNC TURNING AND MACHINING

Favoured Prototype Specialist since 1924

CNC turning and milling – For maximum precision

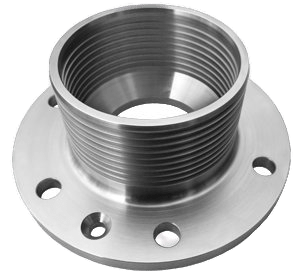

Our specialty is 5-axis CNC machining. Our extensive assortment of machining equipment is continuously updated with the latest CNC technology. Among other things, we have 5-axis machining centers and Integrex multi-tasking machines with sub-spindles, CNC steady rest and CNC controlled tailstock.

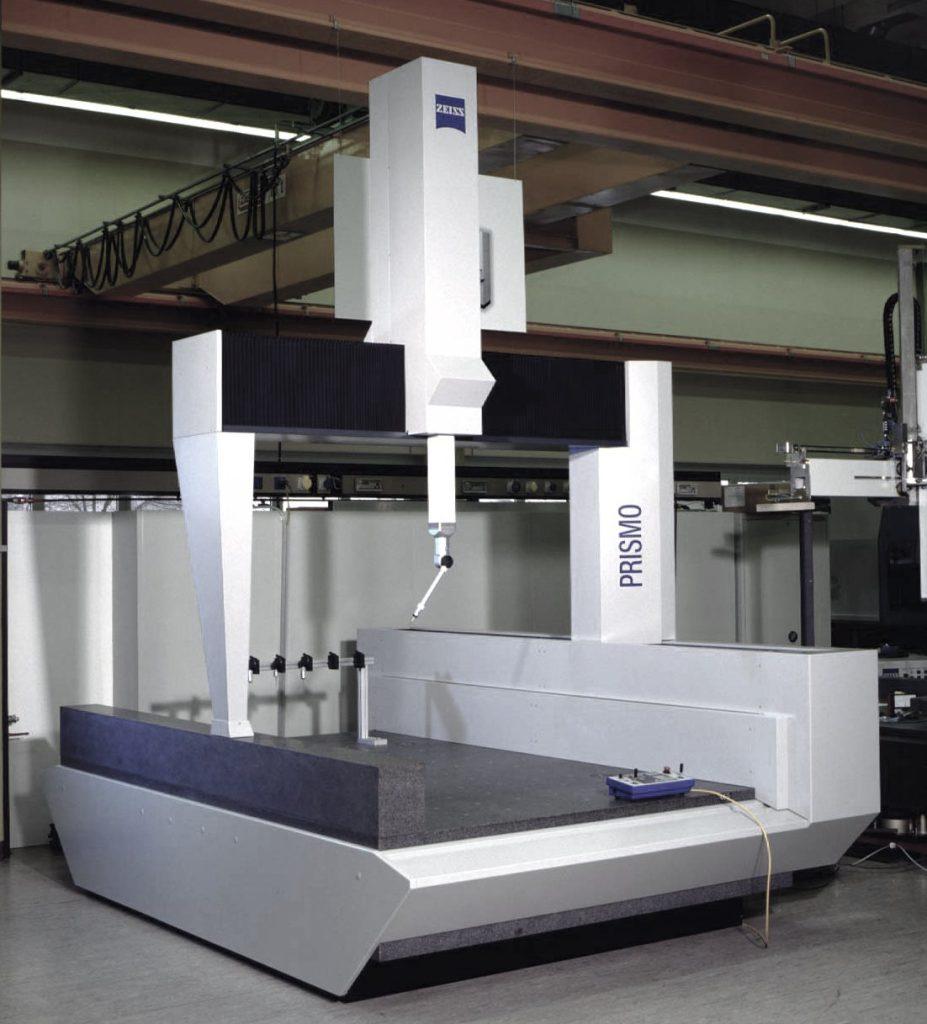

We specialize in the manufacture of precision parts of a very high-quality finish, and we produce everything from single pieces to large series and framework agreements. Our quality management is ISO 9001:2015 certified, and our inspection department works with Zeiss 3D coordinate measuring machines.

CNC Turning

The machine park of the A.K.S. Group, which is constantly being upgraded with the latest CNC technology, includes, among other things, 5-axis MAZAK Integrex multi-tasking machines, with a turning diameter of up to 760mm and a turning length of up to 1524mm.

We can turn virtually all types of metal and plastic

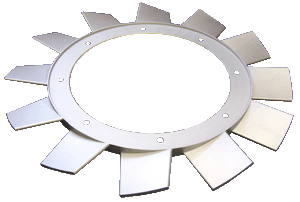

CNC Milling

Our extensive machine park, which is constantly updated with the latest CNC technology includes, among other things, 5-axis Mazak and AXA machining centers, with a working area of up to x 4000mm y 900mm z 950mm.

5-axis CNC machining with robotic feeding

When processing on one of our many 5-axis- and robot-operated machining centers, we ensure low production costs, as well as a high degree of quality and precision. The finishing processing of products are made in a set-up, which eliminates errors when moving parts from one machine to another, and ensures that all processing is placed precisely in relation to each other.

Quality Control

In order to ensure our high quality requirements, a well-stocked control department with CMM measuring machines that are constantly calibrated and upgraded with the latest technology, is required. Our control department has 3 CMM measuring machines, profile projector, microscopes, roughness testers, hardness tester, layer thickness gauges, PMI tester, etc. |