DEBURRING

Favoured Prototype Specialist since 1924

Why is deburring required on sheet metal?

- Burrs are sharp edges, left after machining, cutting, or punching.

- Items with burrs do not look like a quality product and from an aesthetic point of view as well as a quality point of view, deburring is recommended.

- Minimizing the risk of injury, caused by sharp edges, on the assembly personnel.

- Burrs can cause problems during assembly.

- Burrs can pose a risk to the correct function of the workpiece.

- Burrs cause problems during surface treatment. On the sharp side, the layer thickness will be thinner than elsewhere, with all its consequences.

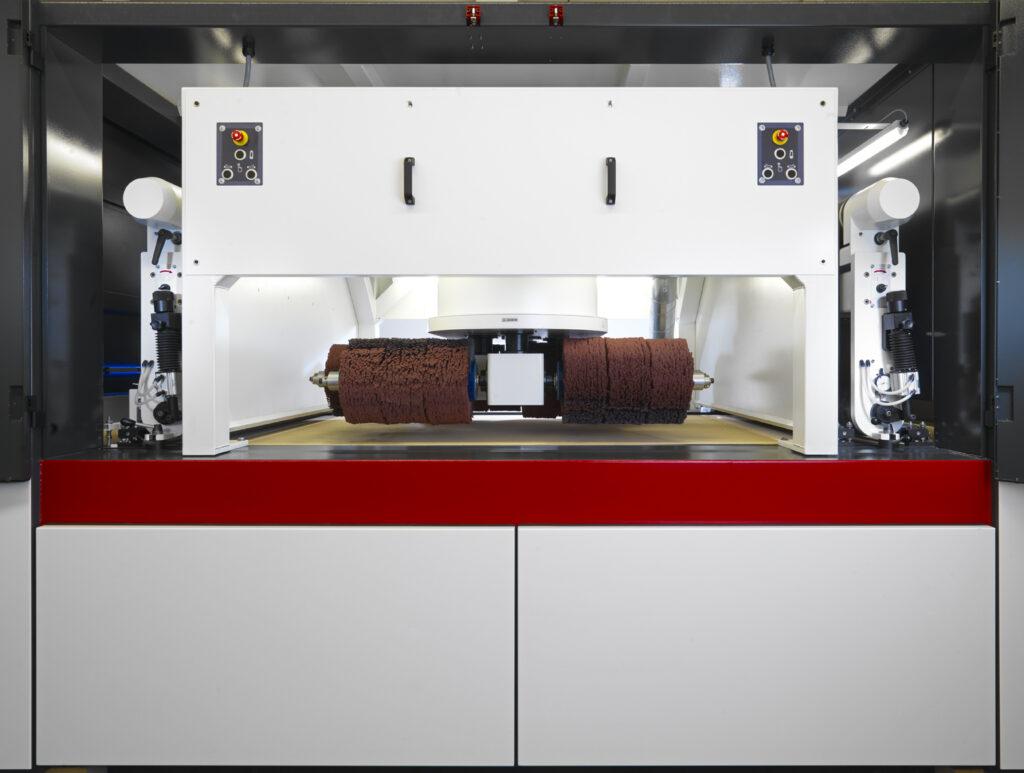

By combining a sanding belt and a brush, products can be deburred and finished in one work step. Our deburring machine is designed for low-cost deburring and post processing of laser cut and punched parts. The Multi Disc head with six rotating deburring discs, creates round edges and a proper finish.

Mechanical Mpecifications:

- Working width: 1350 mm.

- Table opening: 0-100 mm.

We offer grinding and deburring of workpieces in the following materials:

- Aluminum

- Stainless steel

- Coated iron

- Brass

- Copper

A.K.S. has 2 sheet metal deburring machines.