ROLLING

FAVORED PROTOTYPE SPECIALIST SINCE 1924

Rolling is a process used to round materials. The rolling produces an impression on the plate, which creates a certain diameter or radius on the workpiece. This applies e.g. to rounding larger sheets, where the process and quality are ensured by experienced operators, so that the material achieves the perfect rolling for the task.

Many different materials can be rolled such as steel, aluminium, brass, copper etc. Thus, there are an unimaginable amount of possibilities within plate rolling, and the items can be adapted for a wide range of different industries and needs.

PLATE ROLLING

AKS Industries has a large selection of plate rollers in various sizes for different tasks. Our smallest plate roller has a roller diameter of Ø24. Our longest one has a diameter of 4 metres.

As one of the first manufacturers, AKS Industries acquired a 4-roll CNC-controlled rolling mill, able to roll ellipses, ovals and other shapes that are otherwise impossible. The controls provide great precision when rolling shrouds, and cabinets etc.

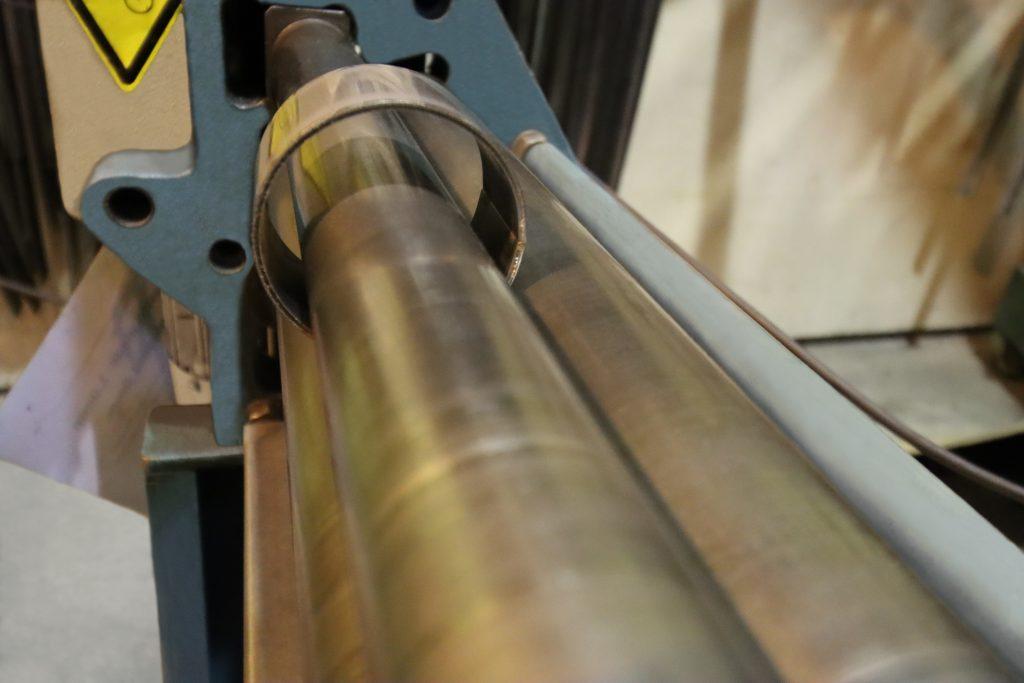

PROFILE ROLLING

AKS offers profile rolling of rod, tube, and profiles, in virtually all types and sizes. In connection with the processing of massive profiles, we have the option to pre-bend the ends, which minimize material waste, and you avoid twisting the material when rolling rings, where you normally roll with an overlap.

Due to AKS’ extensive fleet of machinery and many years of experience, we offer profile rolling of all shapes, including pipes, profiles, etc. in all types of material, regardless of whether this is steel, aluminium, stainless steel etc. Our rolled products are used in many different industries. We offer customized solutions, whether this may be large or small series.

We’re able to roll workpieces, both in large and small radius. Due to our creativity and willingness, we’ll find a solution that’ll make customers’ wishes possible.