TUBE LASER CUTTING

FAVORED PROTOTYPE SPECIALIST SINCE 1924

Tubes and profiles are used in many applications, ranging from mechanical engineering and system construction to the furniture industry.

Tube lasers have opened new construction and design possibilities, and a growing number of people are using the many advantages of laser-cut pipes and profiles for the significant streamlining of production time.

Discover the extensive program of options for cutting pipes and profiles and learn what pipe laser cutting can do for you.

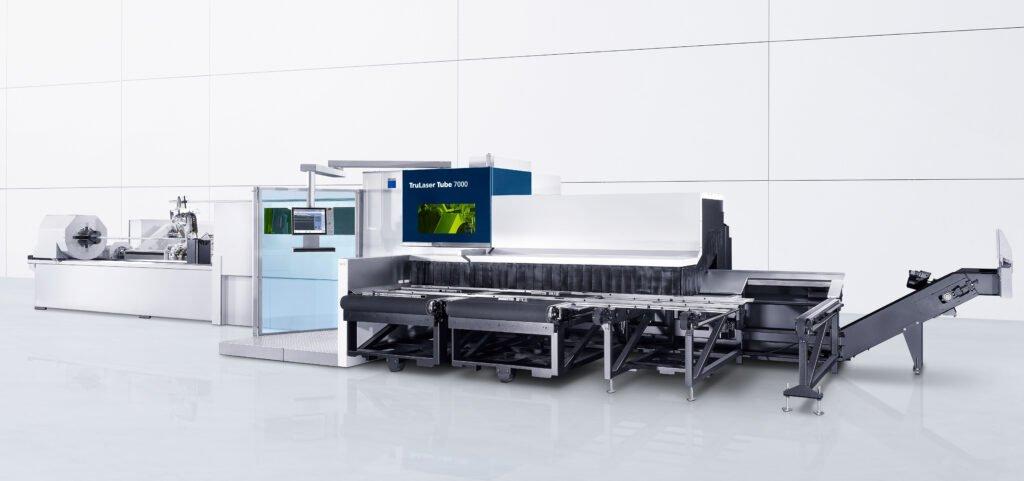

TRUMPH TruLaser Tube 7000

MAX. LASER EFFECT: 6000W

MAX. WORKPIECE WEIGHT: 40 kg/m

MAX. WORKPIECE SIZE: Ø254 x 6500 mm.

MAX. MATERIAL THICKNESS, IRON: 14 mm.

MAX. MATERIAL THICKNESS, STAINLESS STEEL: 10 mm.

MAX. MATERIAL THICKNESS, ALUMINIUM: 10 mm.

MAX. MATERIAL THICKNESS, COPPER: 5 mm.

MAX. MATERIAL THICKNESS, BRASS: 5 mm.

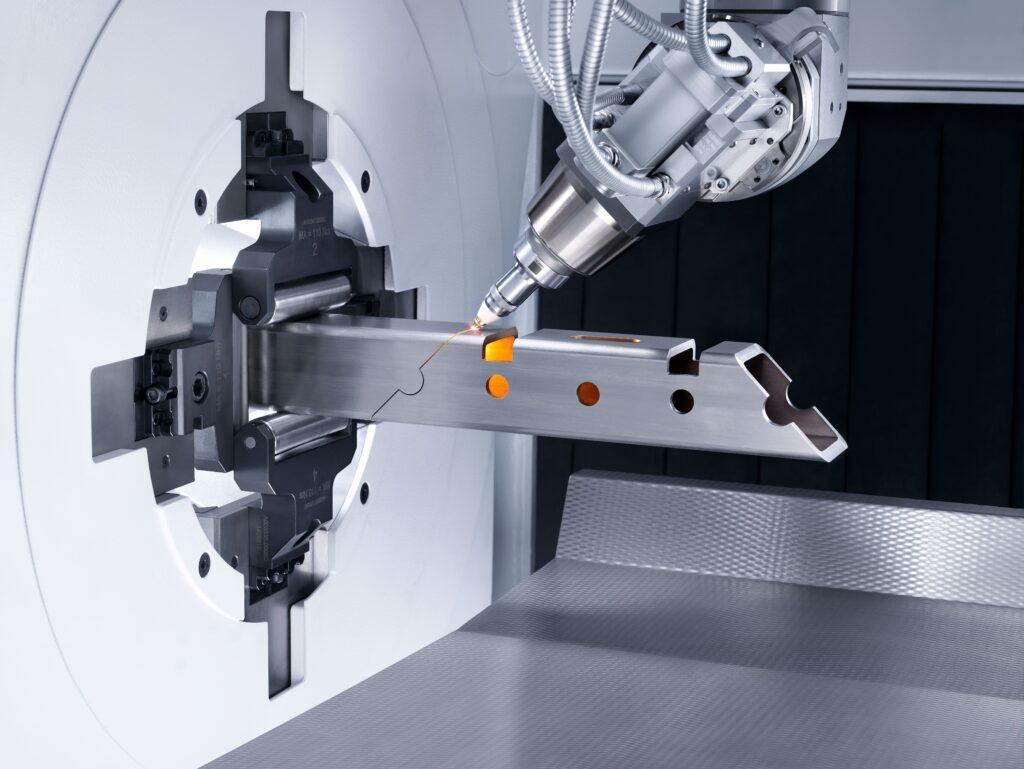

Bevel Cutting

We perform bevel cuts up to 45°, which means that we can cut 90° countersunk holes and prepare bevels for welding.

Automated machining processes such as flow drilling, tapping and threading are integrated into the machine. The automation means you can benefit from reduced handling of parts, reduced machining time and a reduced risk of errors.