QUALITY CONTROL

Favoured Prototype Specialist since 1924

To ensure our high-quality standards, a well-equipped quality department is required, with measuring machines that are constantly calibrated and upgraded with the latest technology.

Our extensive range of plug gauges, ring gauges and thread gauges is registered in the computer system.

Our quality department has 6 CNC measuring machines, a profile projector, microscopes, surface roughness testers, hardness testers, coating thickness gauges, PMI testers, etc.

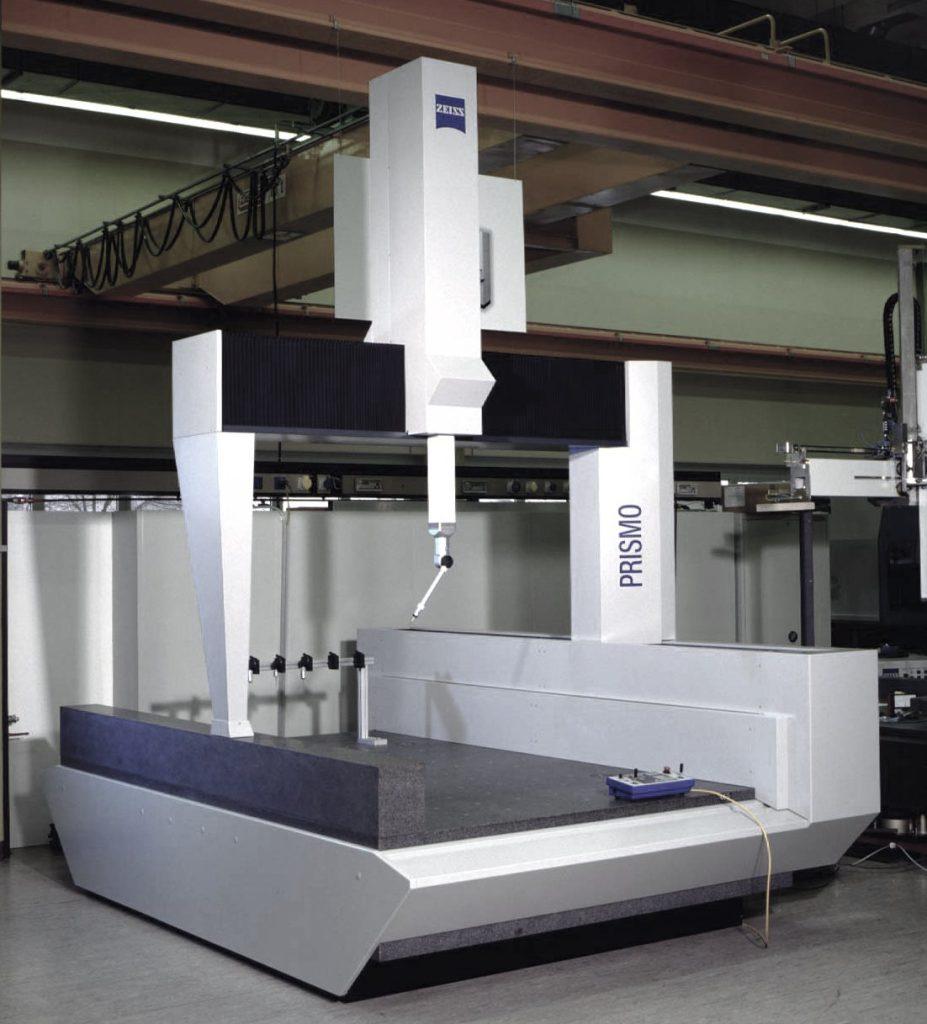

Our largest Zeiss 3D coordinate measuring machine is one of the largest models available in Denmark, with a measuring range of no less than 2400x1200x1000 and equipped with a rotary table of Ø630 mm.

Our high-precision CMM coordinate measuring centers operate using probes, achieving an accuracy of 15 µ (0.0015 mm).

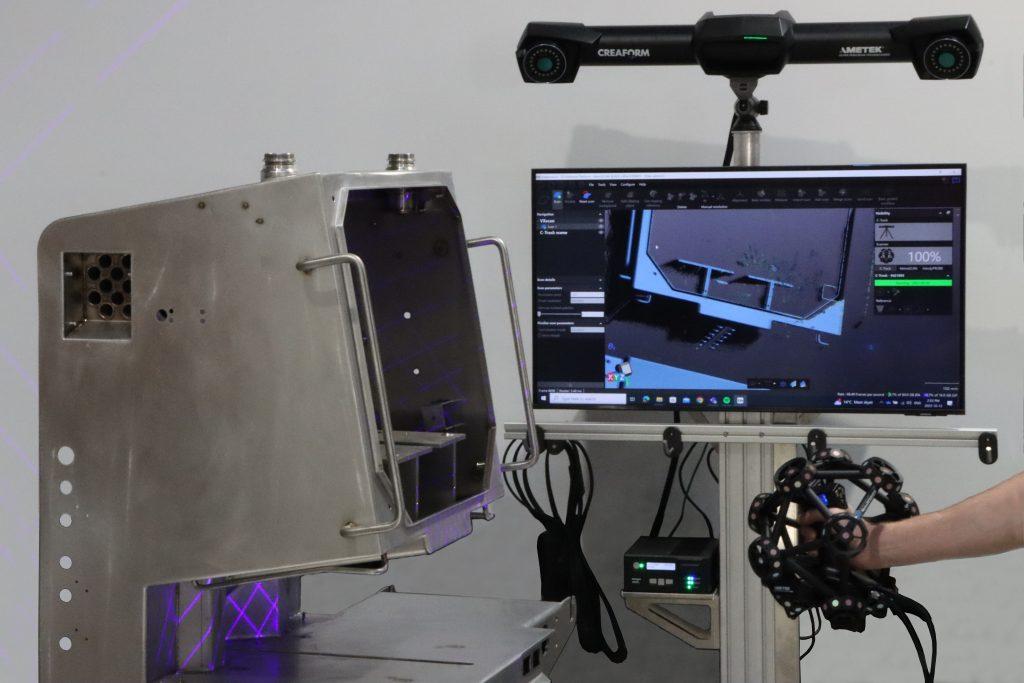

AKS uses several different professional laser measuring systems.

The hallmark of laser scanning is ultra-fast measurement, especially on surfaces.

Laser scanning is a new form of dimensional inspection, and here AKS is also at the forefront. Japanese Keyence has developed the world’s first 3D laser scanner. AKS is the first in the Nordic region to have invested in 3D laser scanning.

Accuracy is up to 15 µ.

In principle, the laser scanner can measure infinitely large workpieces by using reference points.

For larger components we have invested in the Amitek scanner, which provides a measuring accuracy of 0.025 µ on areas less than 3 m2. For measurements up to 16 m2 the accuracy is 0.04 µ.

We carry out measurement tasks for both customers and competitors, also as on-site assignments.